Introduction:

In many industrial sectors, corrosion remains a significant and costly problem. Whether in chemical processing plants, offshore oil rigs, or high-temperature environments, materials are constantly exposed to aggressive substances that deteriorate metals over time. Traditional stainless steels often fall short when faced with such harsh conditions, leading to frequent maintenance, downtime, and expensive replacements.

This is where high-performance alloys like Stainless Steel 317L come into play—specifically in the form of Stainless Steel 317L Sheets.

Product Introduction:

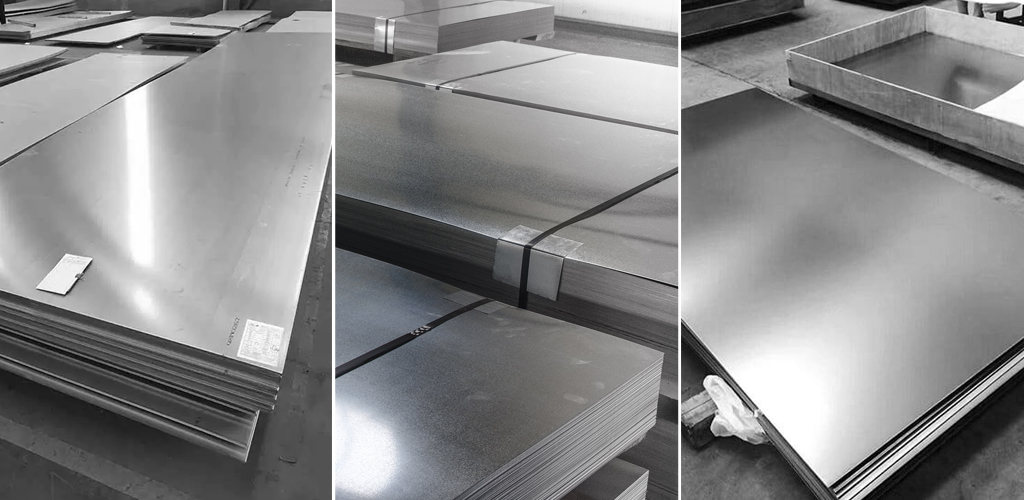

Stainless Steel 317L Sheets are flat-rolled metal products made from an austenitic chromium-nickel-molybdenum alloy with low carbon content. Designed in compliance with international standards such as ASTM A240 / ASME SA240, these sheets offer superior corrosion resistance compared to conventional stainless steels like 304 or 316.

They are produced by trusted Stainless Steel 317L Sheets Manufacturers and are widely available in various thicknesses and finishes to meet diverse industrial needs.

Key Advantages of Stainless Steel 317L Sheets

-

Exceptional Corrosion Resistance

Thanks to its higher molybdenum content, SS 317L sheets resist pitting and crevice corrosion better than many other stainless steel grades, especially in chloride environments. -

High Temperature Strength

These sheets retain strength and resist oxidation even at elevated temperatures, making them suitable for high-heat applications. -

Low Carbon Content

The low carbon composition minimizes the risk of carbide precipitation during welding, enhancing weldability and resistance to intergranular corrosion. -

Excellent Formability and Fabrication

Stainless Steel 317L Sheets can be easily fabricated using standard welding and forming techniques. -

Compliance with Global Standards

Manufactured under ASTM A240 / ASME SA240 ensures quality, consistency, and performance across industries.

Real-Life Uses: Where Are They Used?

-

Chemical and Petrochemical Industry: Reactors, heat exchangers, and tanks

-

Marine Applications: Boat fittings, offshore rigs, and desalination equipment

-

Pharmaceutical Industry: Cleanroom equipment, sterilizers, and production tanks

-

Pulp and Paper Mills: Digester tanks and bleaching equipment

-

Food Processing Units: Storage tanks, processing lines, and hygienic surfaces

Problem Solved & Outcomes

By using Stainless Steel 317L Sheets in place of lower-grade stainless steels or carbon steel, industries can significantly extend the service life of their equipment in corrosive environments. This switch reduces:

-

Maintenance Costs: Fewer repairs and replacements required

-

Operational Downtime: Higher reliability under extreme conditions

-

Safety Risks: Better material integrity enhances structural safety

-

Environmental Impact: Less material waste due to fewer failures

The outcome? A cost-effective, sustainable, and reliable solution for industries that operate in demanding conditions.

Conclusion

Stainless Steel 317L Sheets are more than just metal sheets—they’re a high-performance solution engineered to withstand the most challenging industrial environments. Backed by global standards like ASTM A240 and ASME SA240, and offered by trusted Stainless Steel 317L Sheets Manufacturers, this alloy is the smart choice for anyone looking to invest in durability, corrosion resistance, and long-term value.